Cold sheet metal working mould design service

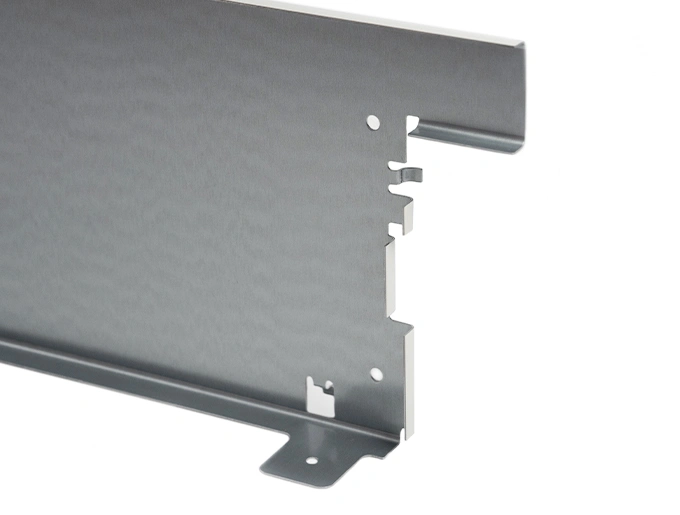

Moulds for cold deformation of sheet metal

MP has established a strong collaboration network with external partners, offering a comprehensive design and production service for moulds used in cold sheet metal processing.

This service is tailored to meet the specific requirements of various sectors and provides the necessary degree of customisation for each project.

MP carefully oversees every stage of the process, from design through to moulding, ensuring excellent outcomes and high-quality moulds that precisely meet the requirements for the specified sheet metal processing.

The service is certified according to the UNI EN ISO 9001:2015 standard, ensuring high production flexibility and safety.

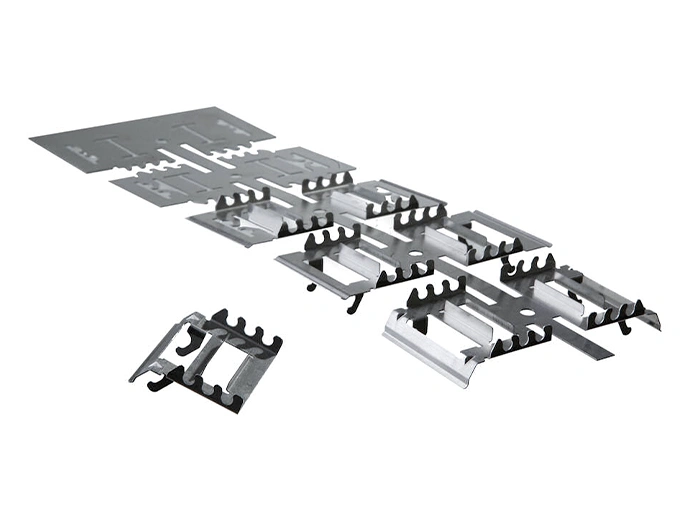

Progressive moulds

Progressive moulds are designed to handle materials of precise thicknesses, ensuring maximum efficiency and precision while offering tailored solutions based on customer requirements. This type of die combines multiple operations—such as punching, drawing, and shearing—performed simultaneously, eliminating the need for manual restarts. This approach reduces processing cycles and associated costs for components.

Drawing phase

The drawing phase shapes sheet metal into cup-shaped, cylindrical, or box-like forms through plastic deformation. This process efficiently creates complex components.

Shearing phase

During the shearing phase, sheet metal is cut into smaller pieces using punches and dies, enabling the precise and rapid formation of machined parts.

Tapping Phase

In the tapping phase, threads are created inside a material using a specialized tool called a tap, which features helical grooves on its external walls. This process enables the creation of precise and functional threads.

Bending Phase

During the bending phase, sheet metal is shaped using a dedicated cold-working mould to achieve desired angles or curved forms.

Coining Phase

The coining phase allows for the creation of typical features such as V-shapes, knurls, housing seats, bevels, as well as adjustments in thickness.

Transfer moulds

Transfer moulds are designed to complete a process in a single operation, such as shearing, bending, calibration, and more. The name stems from their ability to finish machining a piece previously processed using progressive dies.

These moulds also work as an alternative to progressive dies, ensuring high-quality final results tailored to specific customer requirements.

Processes achievable with transfer moulds include:

Deep drawing

Blanking

Tapping

Folding

Coining

Your sole partner for cold sheet metal forming

Estimation

MP provides a rapid and accurate quoting service with a detailed project analysis focusing on potential challenges and alternative solutions.

Design and Co-design

MP offers complete mould design and co-design services in collaboration with customers. Our focus is on developing solutions for fully automated processes to reduce time and material consumption.

Prototyping

MP develops prototypes according to customer specifications in preparation for final mould production. These prototypes undergo evaluation and refinement to ensure readiness for large-scale production.

Industrialization

Following prototyping comes industrialization, the process of transformation from prototype to large-scale production. This phase includes optimising MP's production processes, implementing specialized equipment and machinery, and standardizing methods and materials for efficient and consistent product manufacturing.

Precision, quality control, and maintenance

Precision, quality control, and maintenance are the cornerstones of MP's production, ensuring product conformity and customer satisfaction.

Regular maintenance of our moulds and machinery ensures optimal performance and extends tool life, maintaining high-quality moulding.

MP has recently collaborated with external designers to innovate mould construction, enabling quicker adjustments. New sensors reduce tooling and maintenance times, allowing us to delay charging customers for routine maintenance until the guaranteed quantity is reached.

Cold sheet metal processing

MP specialises in cold working, a plastic deformation process that preserves the mechanical properties of materials, ensuring precise components with high-quality finishes.

Materials we work with

MP excels in cold forming various materials, with expertise in shearing and forming aluminium—a lightweight yet durable material ideal for applications requiring low weight and high thermal conductivity. Each material meets project-specific requirements, ensuring high strength, durability, and precision standards.